Thermal Break: Everything you need to know about these profiles

Did you know that thermal break profiles were less commonly used a decade ago? Thanks to companies like Muller TB Technologies AG, the machinery needed to process thermal break profiles is now widely available. But just what is a thermal break, and why is it such big news?

Buildings are constructed from various materials, including aluminium. Perhaps you make aluminium profiles and are already aware of what an excellent material it is for window and door frames. It's light and durable, it can withstand any type of weather and it's incredibly strong. However, without a thermal break it can cause problems as aluminium is also an effective heat conductor. Without a thermal break, your aluminium profile will be very hot in the sun and very cold in snow and rain. In effect, it draws heat in or out of its surroundings so if profiles today didn't have a thermal break we would face some of the problems that were common in the past. These include condensation, mould and dampand with no thermal break in frames your building would be cold in winter and hot and stuffy in summer. Not only is damp and condensation unpleasant, window frames without a thermal break can mean higher bills for heating. In extreme cases, damp can cause structural damage, so it's easy to see why thermal break profiles are the smart choice.

So what exactly is a thermal break?

A thermal break is, quite simply, a piece of material that's inserted between two pieces of aluminium. Today's thermal break material is normally made from a durable polyamide material. Until recently, however, aluminium thermal break window frames were made using a technique called pour and debrided. These vintage aluminium frames were made in one piece using an extrusion technique and were quite different to the thermal break profiles we deal with today. The frames would then be sliced in two so that two half scales are created. The hardened polyurethane holds the two pieces together. By comparison, modern thermal break material is about 1,000 times less conductive than the surrounding aluminium and that's an incredible amount of heat saved. This type of thermal break is created by inserting thin strips of polyamide into frames that are made in two separate halves.

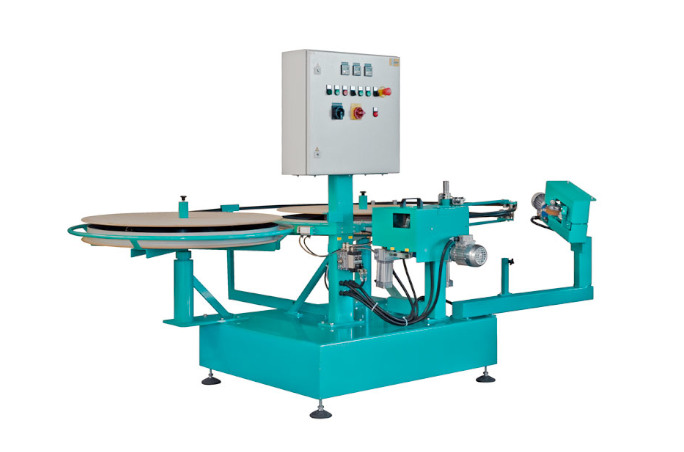

If your company makes thermal break profiles, you'll know just how accurate they are and how precisely they fit together when assembled using machinery such as that made by Muller TB Technologies AG. Muller was one of the companies that lead the way in developing new thermal break insertion techniques. Its exceptional machines can make every stage of your assembly easier and you can see some examples now at www.muller.ch.

This may as well be of interest to you:

- Knurling machine: How can a knurling machine change your life?

- Muller AG: rolling machine manufacturers for today

- Taping machine: Get the best results with a taping machine

- Thermal Break: Everything you need to know about these profiles

- Thermal strip: Make thermal strip processing simple and efficient

- Weather stripping for doors and windows: the advantages